In today’s rapidly evolving industrial landscape, CNC machines have become a cornerstone of manufacturing and production technologies. But what does CNC mean? At its core, CNC stands for Computer Numerical Control, a revolutionary process that automates the control of machining tools using computer programming. This advanced technology has not only streamlined manufacturing processes but has also enhanced precision, efficiency, and scalability in industries worldwide.

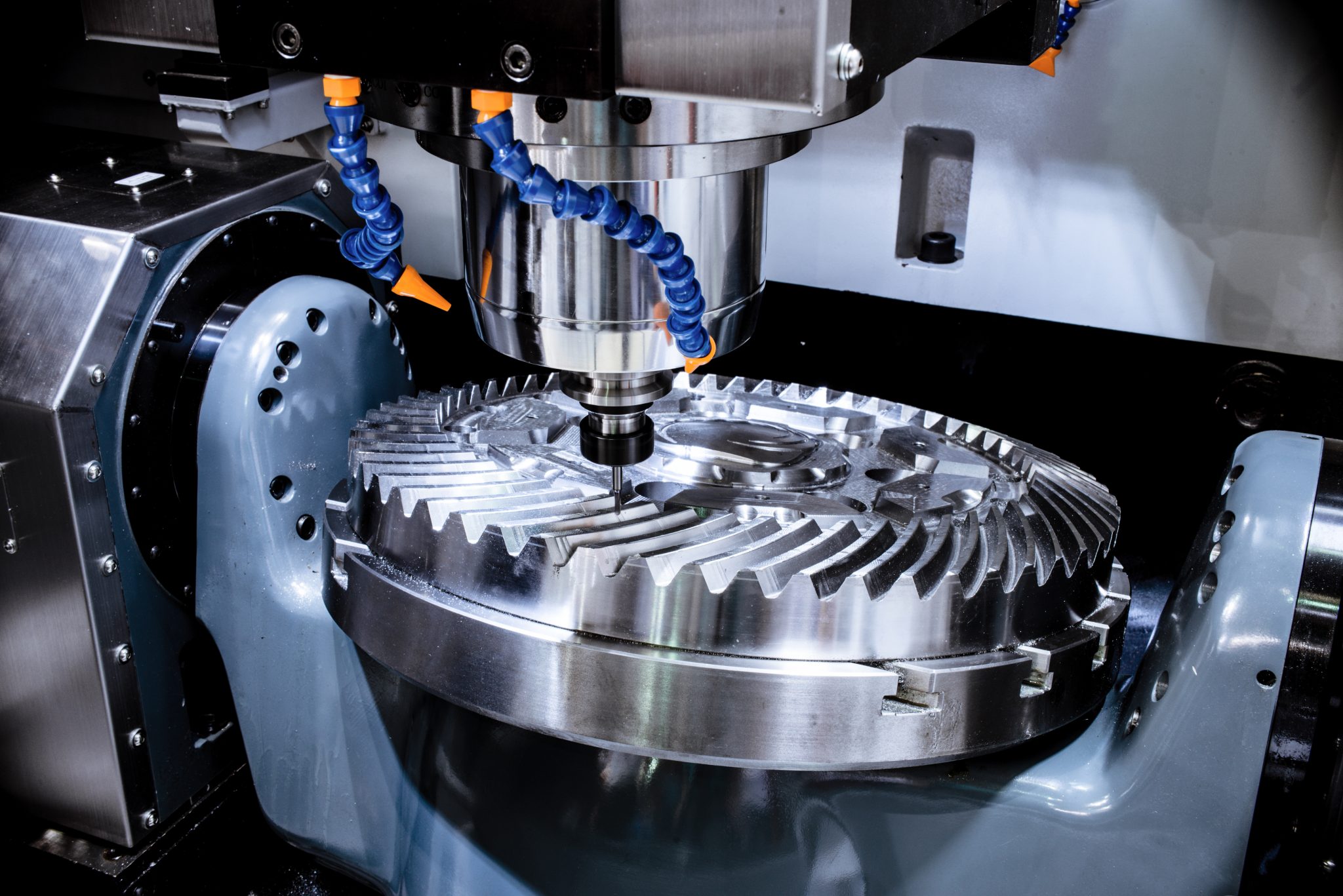

Over the years, CNC technology has evolved into a sophisticated and indispensable tool for industries ranging from automotive to aerospace, healthcare, and beyond. Unlike traditional manual machining, CNC machines rely on software to execute complex designs with unmatched accuracy and consistency. Whether it’s carving intricate patterns, cutting materials, or assembling components, CNC machines have redefined modern manufacturing by ensuring high-quality results in less time.

This article delves deep into the meaning of CNC, the history behind its development, its various types, and how it has reshaped industries worldwide. We’ll explore the advantages of CNC technology, its practical applications, and the challenges it presents to manufacturers. By the end of this comprehensive guide, you’ll have a clear understanding of why CNC technology is a vital part of today’s industry and where it’s heading in the future.

Table of Contents

- What Is CNC?

- The History of CNC Machines

- How CNC Machines Work

- Types of CNC Machines

- Applications of CNC Technology

- Advantages of CNC Machines

- Challenges and Limitations of CNC Technology

- CNC Programming

- Materials Used in CNC Machining

- CNC in Modern Industries

- Future of CNC Technology

- Safety Considerations in CNC Machining

- Maintenance of CNC Machines

- CNC vs. Traditional Machining

- Frequently Asked Questions

What Is CNC?

CNC, short for Computer Numerical Control, refers to the automated control of machining tools such as drills, lathes, mills, and 3D printers through pre-programmed computer software. Unlike manual machining, where an operator must guide the tool physically, CNC machines allow for precise, programmable instructions to dictate every movement. This ensures consistent and accurate production, even for complex designs.

The concept is rooted in the idea of translating digital designs into physical objects. By using CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software, engineers can create intricate blueprints that CNC machines then bring to life. From cutting and shaping materials to assembling components, CNC technology has a vast range of capabilities.

One of the key aspects of CNC technology is its ability to repeat tasks with exceptional precision. This makes it invaluable for industries requiring mass production or high levels of accuracy, such as aerospace, automotive, and medical device manufacturing.

The History of CNC Machines

The journey of CNC machines began in the mid-20th century, during a period of rapid industrialization and technological innovation. Initially, machining processes were manually operated, requiring skilled technicians to handle tools and equipment. However, as industries grew and demand for higher precision increased, the limitations of manual machining became apparent.

In the 1940s, the concept of numerical control (NC) was introduced, which relied on punched tape to automate machine movements. This was a significant breakthrough, as it allowed for greater consistency and efficiency. Over time, advancements in computing technology led to the development of CNC, where computers replaced punched tape to automate the process further.

By the 1970s, CNC machines became more accessible and versatile, revolutionizing manufacturing across various sectors. Today, they are an integral part of modern industry, enabling the production of everything from microchips to airplane components with unparalleled precision.

How CNC Machines Work

CNC machines operate based on a set of instructions called G-code, which dictates the movements and operations of the machine. These instructions are typically generated using CAD/CAM software, which allows designers to create digital models of the desired product.

Once the G-code is loaded into the CNC machine, the computer interprets the code and sends signals to the machine's motors and actuators. These components control the movement of the tool and the workpiece, ensuring precise execution of the programmed design. The process may involve cutting, drilling, milling, or other operations, depending on the type of CNC machine and the material being worked on.

CNC machines are equipped with sensors and feedback systems to monitor their performance in real-time. This ensures that any deviations from the programmed path are corrected immediately, maintaining the accuracy and quality of the final product.

Types of CNC Machines

CNC machines come in various types, each designed for specific applications. Some of the most common types include:

- CNC Milling Machines: Used for cutting and shaping materials with rotary tools.

- CNC Lathes: Ideal for producing cylindrical parts by rotating the workpiece against a cutting tool.

- CNC Routers: Commonly used for cutting wood, plastic, and soft metals.

- CNC Plasma Cutters: Utilize plasma torches to cut through electrically conductive materials.

- CNC EDM (Electrical Discharge Machines): Use electrical discharges to shape hard materials like metal.

- 3D Printers: A type of CNC machine that creates objects layer by layer using additive manufacturing techniques.

Each type of CNC machine has unique capabilities, making it suitable for different industries and applications.

Applications of CNC Technology

CNC technology is incredibly versatile and is used across a wide range of industries, including:

- Aerospace: Manufacturing precision components for aircraft and spacecraft.

- Automotive: Producing engine parts, gears, and other critical components.

- Healthcare: Creating surgical instruments, prosthetics, and medical devices.

- Electronics: Fabricating circuit boards and other electronic components.

- Construction: Designing architectural models and custom building materials.

The adaptability of CNC technology makes it a cornerstone of modern manufacturing, enabling the production of complex and high-quality products efficiently.

Advantages of CNC Machines

CNC machines offer numerous benefits over traditional machining methods, including:

- Precision: Achieve high levels of accuracy and consistency.

- Efficiency: Reduce production time and increase output.

- Flexibility: Easily adapt to different designs and materials.

- Cost-Effectiveness: Lower labor costs and minimize material waste.

- Safety: Reduce the risk of human error and workplace accidents.

These advantages make CNC machines an essential tool for industries seeking to optimize their manufacturing processes.

Frequently Asked Questions

- What does CNC stand for? CNC stands for Computer Numerical Control.

- What industries use CNC technology? Industries such as aerospace, automotive, healthcare, and electronics heavily rely on CNC technology.

- How does CNC machining differ from traditional machining? CNC machining is automated and computer-controlled, whereas traditional machining relies on manual operation.

- What materials can be used in CNC machining? CNC machines can work with metals, plastics, wood, and composites.

- How long does it take to program a CNC machine? The time required depends on the complexity of the design and the programmer's expertise.

- Are CNC machines cost-effective? Yes, CNC machines reduce labor costs, minimize material waste, and increase production efficiency.

For more in-depth information on CNC technology, you can visit Engineering.com.

Article Recommendations

- The Ultimate Guide To Frank Rafaraci Your Source For Expert Insights

- Carson Rowland

- Uncover The Value Costco One Day Membership At An Exceptional Price