In an internal combustion engine, the connecting rod is a critical component that facilitates the transfer of energy from the crankshaft to the piston. It acts as a link between these two vital parts, ensuring the smooth and efficient operation of the engine.

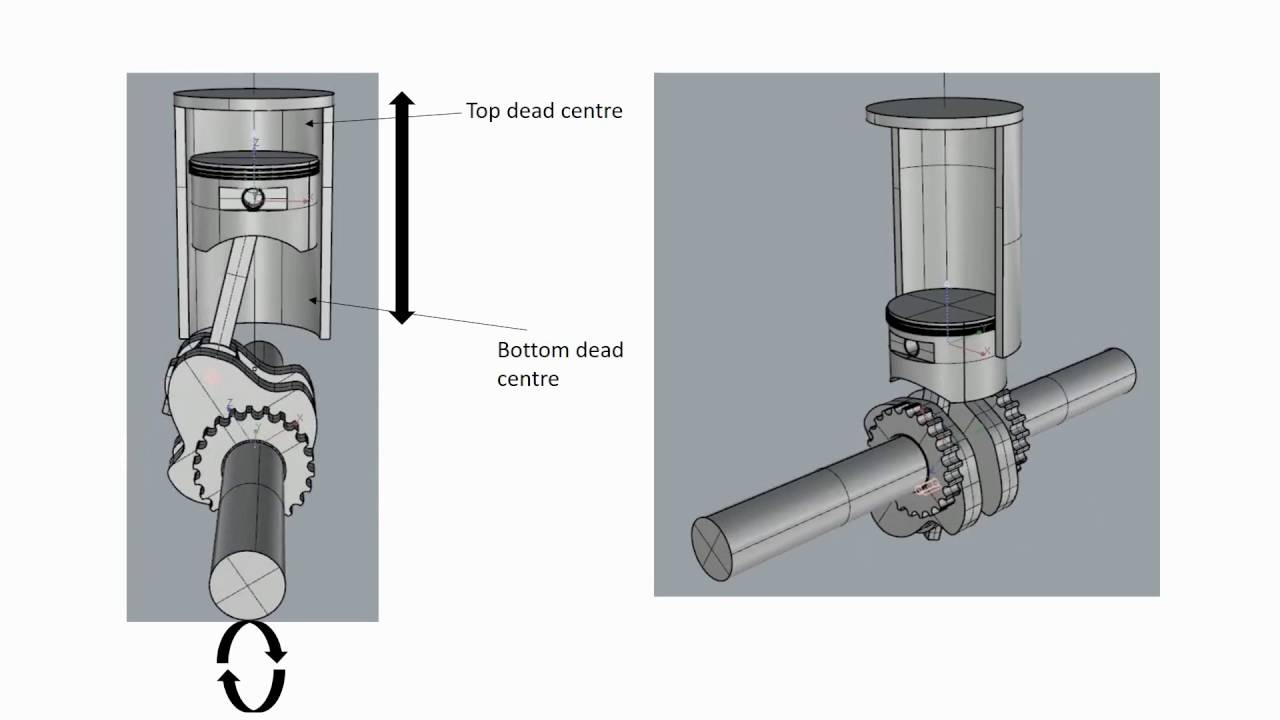

The connecting rod plays a crucial role in converting the rotary motion of the crankshaft into the reciprocating motion of the piston. As the crankshaft rotates, the connecting rod translates this motion to the piston, causing it to move up and down within the cylinder. This reciprocating motion is essential for the engine's combustion process, as it allows for the intake and exhaust of gases, as well as the compression of the air-fuel mixture.

The connecting rod is typically made from high-strength materials, such as forged steel or aluminum alloys, to withstand the significant forces and stresses it encounters during engine operation. Its design and dimensions are carefully engineered to ensure proper alignment and minimize friction between the crankshaft and piston.

Overall, the connecting rod is an indispensable component in internal combustion engines, enabling the efficient transfer of energy from the crankshaft to the piston. Its robust construction and precise design contribute to the overall performance and reliability of the engine.

The Connecting Rod

The connecting rod plays a crucial role in internal combustion engines, facilitating the transfer of energy from the crankshaft to the piston. Key aspects of this process include:

- Conversion: Transforming rotary motion into reciprocating motion.

- Linkage: Connecting the crankshaft and piston.

- Force Transmission: Transferring energy between the two components.

- Materials: High-strength materials (e.g., forged steel) withstand significant forces.

- Design: Precise dimensions and alignment ensure efficient operation.

- Combustion: Enables the intake, exhaust, and compression of gases.

- Performance: Contributes to the overall performance and reliability of the engine.

In summary, the connecting rod is a vital component in internal combustion engines, enabling the efficient transfer of energy from the crankshaft to the piston. Its robust construction and precise design contribute to the overall performance and reliability of the engine. Understanding these key aspects provides a deeper insight into the critical role of the connecting rod in the functioning of internal combustion engines.

1. Conversion

In the context of "the connecting rod transfers the energy of the crankshaft to the piston," the conversion of rotary motion into reciprocating motion is a crucial aspect that enables the engine to function efficiently.

- Mechanism and Function: The connecting rod acts as a lever arm, converting the crankshaft's rotary motion into the piston's reciprocating (up-and-down) motion. This conversion is essential for the proper functioning of the engine, allowing for the intake of air and fuel, compression of the mixture, and exhaust of combustion gases.

- Types of Engines: This conversion principle applies to both reciprocating piston engines (e.g., in cars, motorcycles) and rotary engines (e.g., in some sports cars). In reciprocating piston engines, the connecting rod is directly linked to the piston, while in rotary engines, it is connected to a triangular rotor that converts the rotary motion of the crankshaft into the reciprocating motion of the rotor.

- Efficiency and Performance: The efficiency of this conversion process is critical for engine performance. Factors such as the connecting rod's length, weight, and design influence the timing and duration of the piston's motion, affecting the engine's power output, fuel consumption, and emissions.

- Engineering Challenges: Designing and manufacturing connecting rods involves addressing engineering challenges related to material strength, durability, and friction reduction. The connecting rod must withstand high forces and stresses while maintaining its structural integrity and minimizing energy losses due to friction.

Overall, the conversion of rotary motion into reciprocating motion, facilitated by the connecting rod, is a fundamental principle in the operation of internal combustion engines. Understanding this conversion process provides insights into the design, efficiency, and performance of these engines.

2. Linkage

In the context of "the connecting rod transfers the energy of the crankshaft to the piston," the linkage between the crankshaft and piston is a crucial aspect that enables the conversion of rotary motion into reciprocating motion.

- Mechanical Connection: The connecting rod mechanically links the crankshaft and piston, allowing them to move in a coordinated manner. It acts as a bridge between these two components, facilitating the transfer of forces and energy.

- Leverage and Force Transmission: The connecting rod acts as a lever, amplifying the force exerted by the crankshaft and transmitting it to the piston. This lever action allows the piston to move with greater force and precision.

- Timing and Synchronization: The connecting rod ensures proper timing and synchronization between the crankshaft and piston. As the crankshaft rotates, the connecting rod guides the piston's movement, ensuring that it reaches the top and bottom of the cylinder at the appropriate moments.

- Durability and Reliability: The connecting rod must be durable and reliable to withstand the high forces and stresses it experiences during engine operation. Its design and materials play a critical role in ensuring the longevity and reliability of the engine.

Overall, the linkage between the crankshaft and piston, facilitated by the connecting rod, is a fundamental aspect of internal combustion engines. It enables the efficient conversion of rotary motion into reciprocating motion, which is essential for the proper functioning of the engine.

3. Force Transmission

In the context of "the connecting rod transfers the energy of the crankshaft to the piston," force transmission is a crucial aspect that enables the conversion of rotary motion into reciprocating motion. The connecting rod acts as a lever, transmitting the force exerted by the crankshaft to the piston, allowing it to move with greater force and precision.

- Mechanical Advantage: The connecting rod provides a mechanical advantage by amplifying the force exerted by the crankshaft. This allows the piston to overcome the resistance of the compressed air-fuel mixture and move efficiently within the cylinder.

- Directional Change: The connecting rod changes the direction of the force transmitted from the crankshaft. The crankshaft's rotary motion is converted into the piston's reciprocating motion, which is essential for the intake, compression, combustion, and exhaust processes in the engine.

- Energy Transfer: The connecting rod facilitates the transfer of energy from the crankshaft to the piston. This energy is used to compress the air-fuel mixture, generating the force that drives the piston downward during the power stroke.

- Material Strength: The connecting rod must be made of high-strength materials to withstand the significant forces it experiences during engine operation. These forces include tension, compression, and bending, which can be amplified by the lever action of the connecting rod.

Overall, force transmission is a key aspect of the connecting rod's function in transferring energy from the crankshaft to the piston. Understanding this force transmission process provides insights into the design, efficiency, and performance of internal combustion engines.

4. Materials

In the context of "the connecting rod transfers the energy of the crankshaft to the piston," the use of high-strength materials for the connecting rod is crucial for its ability to withstand the significant forces it experiences during engine operation.

The connecting rod is subjected to various forces, including tension, compression, and bending. These forces are generated by the combustion process, the reciprocating motion of the piston, and the rotation of the crankshaft. High-strength materials, such as forged steel, are essential for ensuring the connecting rod's structural integrity and preventing catastrophic failure.

Forged steel, in particular, offers a combination of strength, durability, and resistance to wear and fatigue. It undergoes a forging process that involves shaping the material under high pressure and temperature, resulting in a refined grain structure and improved mechanical properties. This makes forged steel an ideal choice for connecting rods in high-performance engines, where reliability and durability are paramount.

The use of high-strength materials for the connecting rod has practical implications for the overall performance and lifespan of the engine. A strong and durable connecting rod can withstand the rigors of engine operation, reducing the risk of failure and costly repairs. It also contributes to the engine's efficiency and power output by minimizing energy losses due to friction and wear.

In summary, the use of high-strength materials for the connecting rod is essential for its ability to transfer energy from the crankshaft to the piston reliably and efficiently. Forged steel is a commonly used material due to its exceptional strength and durability, contributing to the overall performance and longevity of internal combustion engines.

5. Design

In the context of "the connecting rod transfers the energy of the crankshaft to the piston," precise dimensions and alignment of the connecting rod are crucial for efficient operation. The connecting rod's design involves meticulous engineering to ensure proper fitment and movement within the engine.

- Dimensional Accuracy: The connecting rod's length, width, and thickness must be precisely manufactured to ensure proper engagement with the crankshaft and piston. Deviations from the intended dimensions can lead to excessive play or binding, resulting in reduced efficiency and premature wear.

- Alignment and Tolerance: The connecting rod must be aligned precisely with the crankshaft and piston to minimize friction and maximize energy transfer. This involves maintaining tight tolerances during manufacturing and assembly to ensure proper fitment and minimize misalignment.

- Mass Optimization: The connecting rod's weight and mass distribution are carefully optimized to balance strength and efficiency. A heavier connecting rod can increase inertia and reduce engine responsiveness, while an excessively lightweight connecting rod may compromise durability.

- Material Selection: The choice of material for the connecting rod, such as forged steel or titanium, affects its strength, weight, and durability. The material must be able to withstand the high forces and stresses experienced during engine operation.

Overall, the precise design and alignment of the connecting rod ensure efficient energy transfer from the crankshaft to the piston. Improper design or alignment can lead to reduced engine performance, increased wear and tear, and potential failures.

6. Combustion

In the context of "the connecting rod transfers the energy of the crankshaft to the piston," combustion plays a crucial role in facilitating the intake, exhaust, and compression of gases within the engine. This process is essential for the efficient operation and power generation of the engine.

Combustion involves the controlled burning of a fuel-air mixture within the engine's cylinders. This process generates high-pressure gases that drive the piston downward during the power stroke. The connecting rod, in turn, transfers this force from the piston to the crankshaft, converting the reciprocating motion of the piston into rotary motion.

The precise timing and coordination of combustion, intake, and exhaust are critical for optimal engine performance. The connecting rod serves as a vital link between these processes, ensuring that the piston is in the correct position to receive the force generated by combustion and transfer it to the crankshaft.

Without combustion, there would be no force to drive the piston downward and generate power. The connecting rod, therefore, plays a crucial role in harnessing the energy released by combustion and converting it into mechanical energy that can be used to power the vehicle.

7. Performance

In the context of "the connecting rod transfers the energy of the crankshaft to the piston," the connecting rod's performance directly influences the overall performance and reliability of the engine.

- Durability and Longevity:

The connecting rod's ability to withstand high forces and stresses, as well as its resistance to wear and fatigue, contribute to the engine's durability and longevity. A robust connecting rod ensures reliable operation over extended periods, minimizing the risk of breakdowns and costly repairs. - Power Output and Efficiency:

The connecting rod's design and materials affect the engine's power output and efficiency. A lightweight and optimized connecting rod reduces inertia and friction, allowing for more efficient power transfer from the crankshaft to the piston. This translates into improved engine responsiveness and fuel economy. - Emissions Reduction:

By contributing to efficient combustion and reducing friction, the connecting rod plays a role in reducing engine emissions. A well-designed connecting rod can help minimize the release of harmful pollutants into the environment. - Smooth Operation and Noise Reduction:

The connecting rod's precise alignment and balanced design contribute to smooth engine operation and reduced noise levels. This enhances the overall driving experience and comfort for vehicle occupants.

In summary, the connecting rod's performance is intricately linked to the overall performance and reliability of the engine. Its durability, efficiency, and precision contribute to maximizing power output, reducing emissions, providing smooth operation, and ensuring engine longevity.

Frequently Asked Questions

This section aims to address common concerns or misconceptions related to "the connecting rod transfers the energy of the crankshaft to the piston."

Question 1: What is the primary function of the connecting rod in an engine?

Answer: The connecting rod's primary function is to transfer energy from the crankshaft to the piston, converting the crankshaft's rotary motion into the piston's reciprocating motion.

Question 2: Why is the connecting rod made from high-strength materials?

Answer: The connecting rod is subjected to significant forces and stresses during engine operation, including tension, compression, and bending. High-strength materials, such as forged steel, are used to ensure the connecting rod's structural integrity and prevent catastrophic failure.

Question 3: How does the connecting rod contribute to combustion in an engine?

Answer: The connecting rod plays a vital role in the combustion process by transferring the force generated by combustion from the piston to the crankshaft. This force drives the piston downward during the power stroke, converting the energy released by combustion into mechanical energy.

Question 4: What factors influence the efficiency of energy transfer through the connecting rod?

Answer: The efficiency of energy transfer through the connecting rod is influenced by factors such as the connecting rod's weight, design, and material properties. A lightweight and optimized connecting rod reduces inertia and friction, allowing for more efficient power transfer.

Question 5: How does the connecting rod impact engine reliability?

Answer: The connecting rod's durability and resistance to wear and fatigue contribute to the engine's overall reliability. A robust connecting rod ensures reliable operation over extended periods, minimizing the risk of breakdowns and costly repairs.

Question 6: What are the consequences of a damaged or faulty connecting rod?

Answer: A damaged or faulty connecting rod can lead to severe engine damage, including piston failure, crankshaft damage, and catastrophic engine failure. Regular maintenance and timely replacement of worn or damaged connecting rods are crucial for engine longevity and performance.

In summary, the connecting rod plays a critical role in transferring energy from the crankshaft to the piston, facilitating combustion, and contributing to engine efficiency and reliability. Understanding the function and importance of the connecting rod is essential for maintaining optimal engine performance and longevity.

Transition to the next article section: This comprehensive overview of "the connecting rod transfers the energy of the crankshaft to the piston" provides valuable insights into the function, design, and significance of this essential engine component. By addressing common questions and clarifying potential misconceptions, this FAQ section aims to enhance your understanding of the connecting rod's role in the efficient and reliable operation of internal combustion engines.

Tips on Optimizing Connecting Rod Performance

To ensure efficient and reliable operation of the connecting rod, consider the following tips:

Tip 1: Choose High-Quality Materials

Select connecting rods made from high-strength materials, such as forged steel or titanium, which can withstand the significant forces and stresses experienced during engine operation. This helps ensure durability and longevity.

Tip 2: Ensure Precise Dimensions and Alignment

Precise manufacturing and assembly are crucial for proper fitment and alignment of the connecting rod. Deviations from intended dimensions or misalignment can lead to increased friction, reduced efficiency, and premature wear.

Tip 3: Optimize Weight and Mass Distribution

Balance the connecting rod's weight and mass distribution to minimize inertia and improve engine responsiveness. A heavier connecting rod may compromise efficiency, while an excessively lightweight one may reduce durability.

Tip 4: Inspect and Maintain Regularly

Regular inspection and maintenance are essential to monitor the connecting rod's condition. Check for signs of wear, damage, or misalignment. Timely replacement or repair of worn or faulty connecting rods can prevent catastrophic engine failures.

Tip 5: Consider Upgraded Connecting Rods

For high-performance engines or applications requiring exceptional durability, consider upgrading to aftermarket connecting rods designed for increased strength, reduced weight, and improved performance.

Tip 6: Seek Professional Assistance

If you encounter any issues or concerns related to the connecting rod or engine performance, seek professional assistance from a qualified mechanic or automotive technician for proper diagnosis and repair.

Tip 7: Refer to Manufacturer's Specifications

Always refer to the engine manufacturer's specifications for recommended connecting rod maintenance intervals, torque values, and any specific requirements for your particular engine model.

Tip 8: Use High-Quality Lubricants

Proper lubrication is vital for reducing friction and wear on the connecting rod and other engine components. Use high-quality engine oil and follow the recommended maintenance schedule for oil changes.

Conclusion

In summary, the connecting rod plays a pivotal role in the efficient transfer of energy from the crankshaft to the piston, facilitating the reciprocating motion that drives internal combustion engines. Its robust design, precise dimensions, and alignment ensure reliable operation under significant forces and stresses.

Understanding the function and importance of the connecting rod is crucial for maintaining optimal engine performance and longevity. Proper selection of materials, regular inspection and maintenance, and seeking professional assistance when necessary can help prevent failures and ensure the smooth and efficient operation of the engine.

As technology advances and engine designs evolve, the connecting rod will continue to be a critical component, requiring ongoing research and development to optimize its performance and contribute to the overall efficiency and reliability of internal combustion engines.

Article Recommendations